Mirrored from:

Replacing The Cam Belt And Water Pump On The Alfa 4C Coupe (Part 1) (alfaworkshop.co.uk)

Replacing The Cam Belt And Water Pump On The Alfa 4C Coupe (Part 2) (alfaworkshop.co.uk)

Replacing The Cam Belt And Water Pump On

The Alfa 4C Coupe (Part 1)

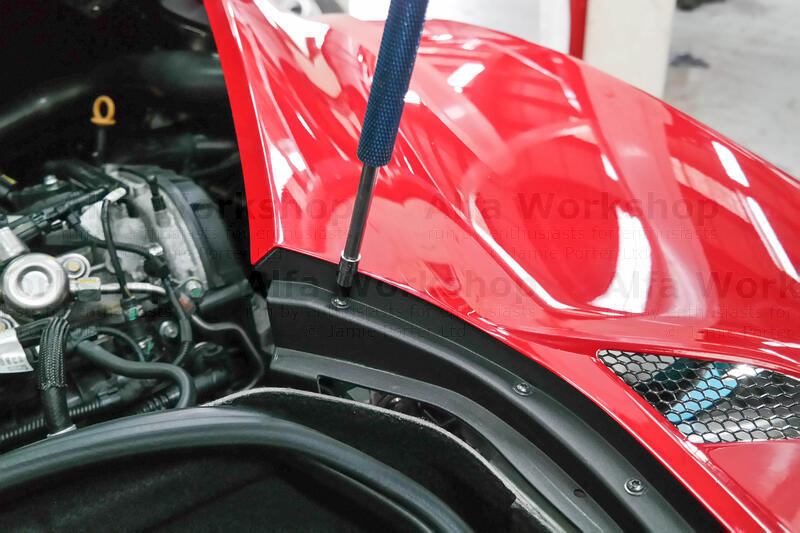

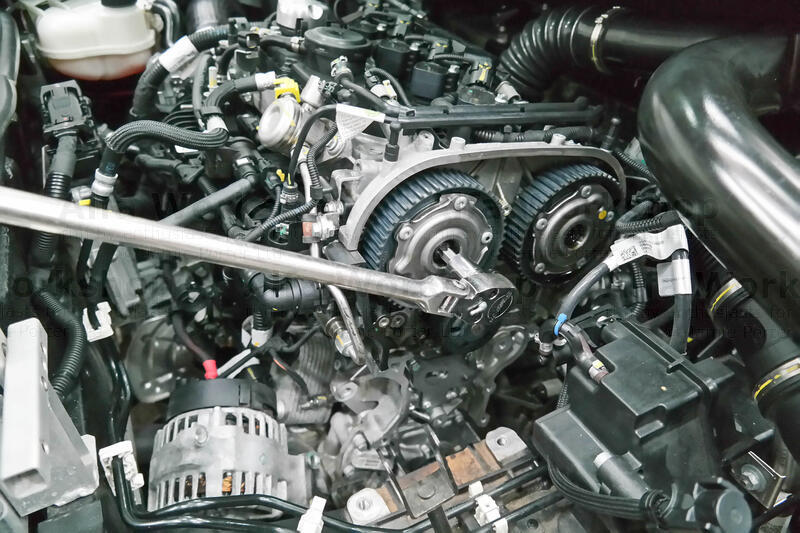

Replacing the cam belt can be done with all the body panels still in place but

we've removed the rear, right side wing to make it easier to see.

WORKSHOP TIME 6hrs

Cam belt kit 6000629434,

water pump 60586222

Gaskets 55213959 and 71779194

If you would like to BOOK yourself

in for a cam belt replacement the price of this service in our workshop

is £668.40 (price

of water pump NOT included).

|

Prop

up the boot and pull off the plastic engine cover.

|

|

|

Undo

the x3 10mm bolts to the breather pipe fixings...

|

|

|

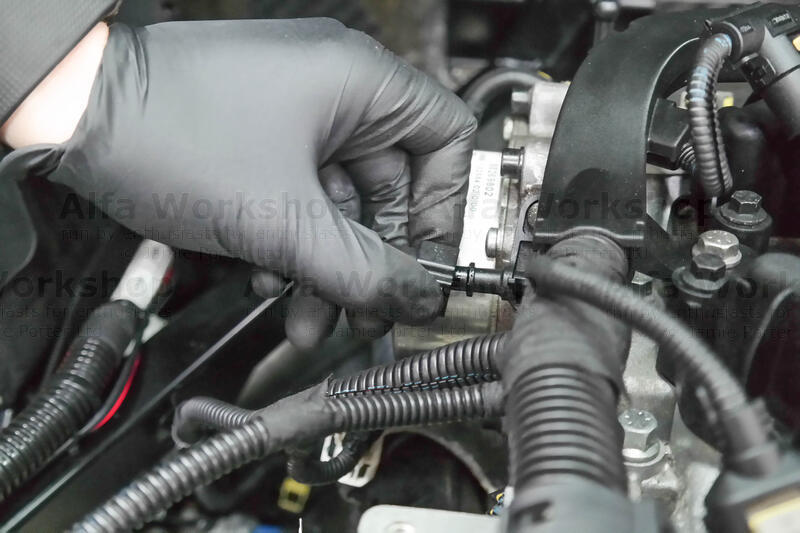

...and

unclip the connector at each end.

|

|

|

Unclip

the vacuum pump hose.

|

|

|

Unplug

the thermostat temp sensor.

|

|

|

Undo

the x4 5mm allen bolts to the vacuum pump and move the pump to one side.

|

|

|

The

inlet camshaft blanking

plate has x3 10mm bolts.

|

|

|

The

undertray is held by x14 T30 (Torx)

screws.

|

|

|

The

rear diffuser has x2 T30, x3 Phillips screws and x4 4mm allen bolts.

|

|

|

Unbolt

the rear RIGHT side wheel and remove.

|

|

|

The

rear RIGHT side wheel arch liner has x3 allen and x3 Phillips screws.

|

|

|

Where

the rear wing joins the bumper there are x5 10mm nuts, remove the first x4

(the last one is in a tight corner).

|

|

|

The

wings alloy support frame has x4 10mm bolts.

|

|

|

There's

a T30 screw at the front of the wheel arch joining the side skirt...

|

|

|

....and

x4 more in the 'door shut'.

|

|

|

In

the top LEFT corner of the 'door shut' behind the weather seal is a 5mm allen

bolt.

|

|

|

There's

x2 T30 screws under the fuel filler flap to a plastic cover and one more

underneath the cover.

|

|

|

Behind

the filler above the filler neck is a 10mm bolt.

|

|

|

Lift

the rubber weather seal around the right side of the boot and undo the T25

screw...

|

|

|

...and

the other x4 along the edge of the black infill panel.

|

|

|

You

can now easily access the fifth 10mm nut joining the rear wing to the bumper.

|

|

|

Carefully

lift the wing away from the car (noting the rear end is sitting on the x5

bumper studs). The drain pipe for the fuel overspill is still connected so

this will pull out with the wing.

|

|

|

With

the wing out of the way you can now work on the engine.

|

|

|

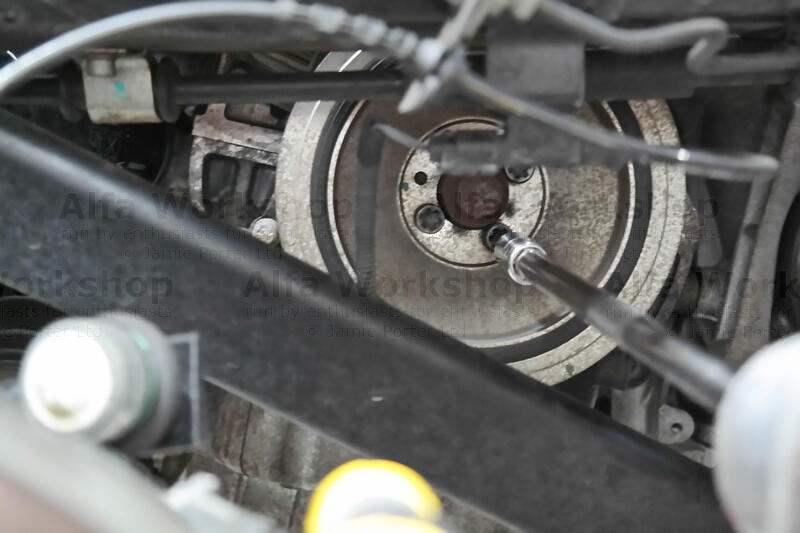

Undo

the x4 T45 bolts to the auxiliary bottom

pulley.

|

|

|

The

auxiliary tensioner mounting bolt is a T47.

|

|

|

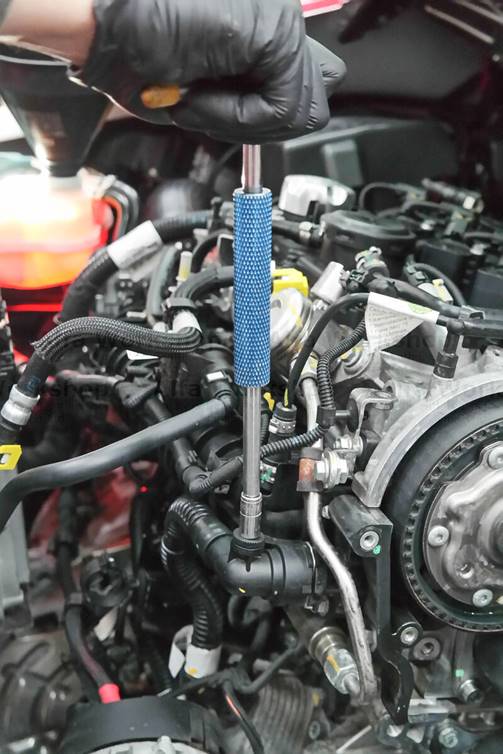

Using

a T50 allen key with an extension bar undo the the auxiliary idler.

|

|

|

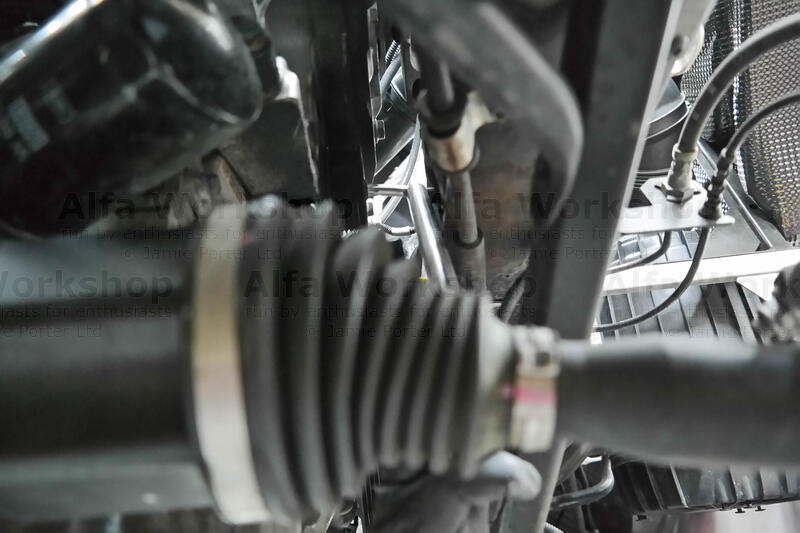

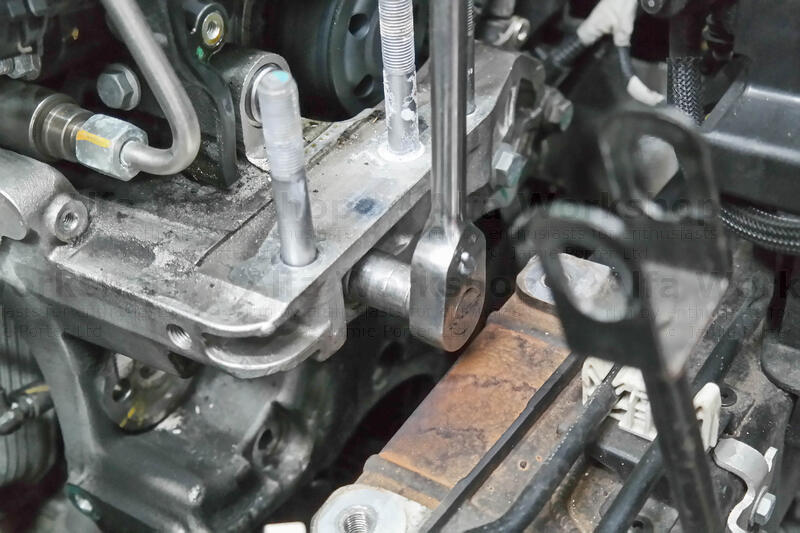

At

the bottom of the engine support (large alloy side casting) are x3 13mm bolts

and x1 15mm.

|

|

|

|

|

|

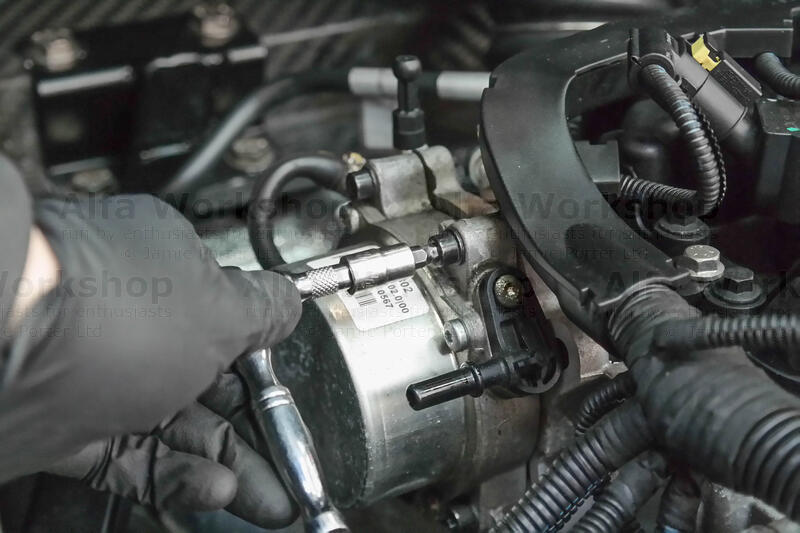

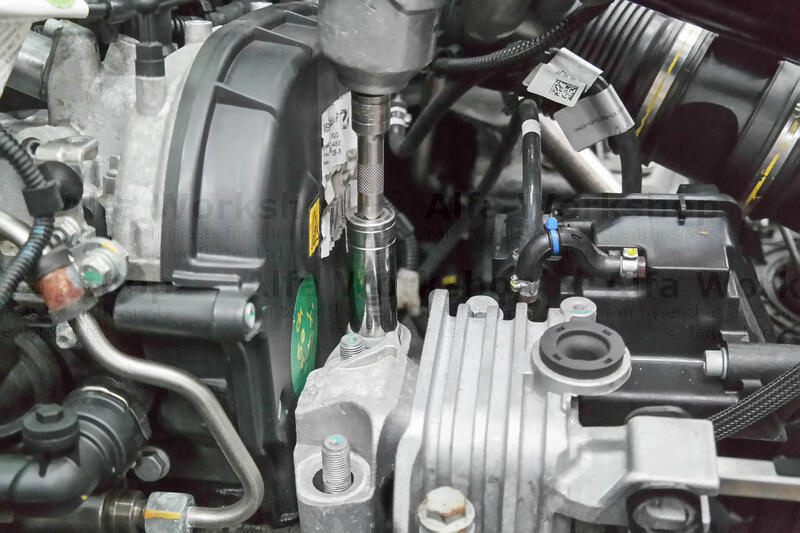

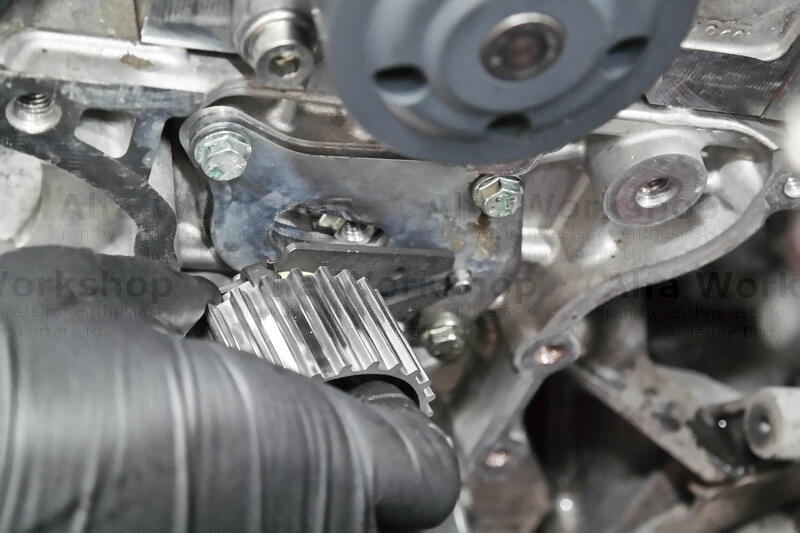

Take

out the oil pumps 10mm bolt and replace it with the timing tool locating pin.

|

|

|

Turn

the crank clockwise with a 19mm spanner until it's aligned with the crank

locking tool then secure with a T45 bolt.

|

Replacing The Cam Belt And Water Pump On

The Alfa 4C Coupe (Part 2)

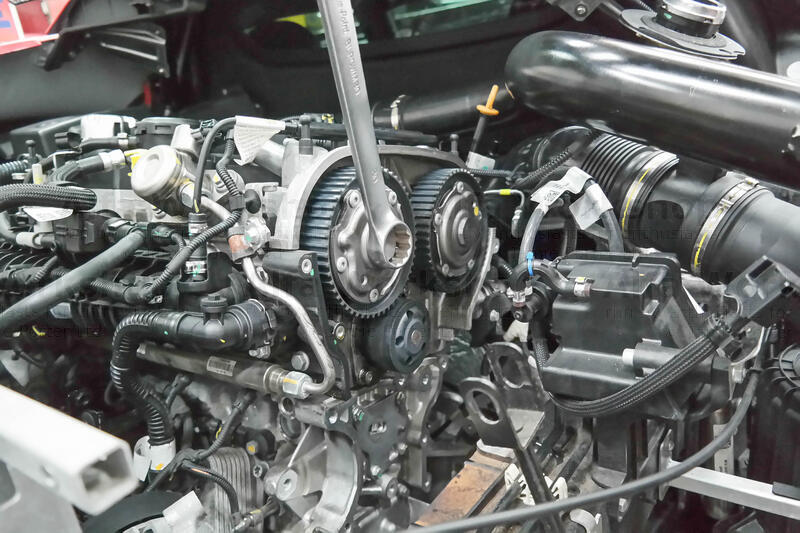

The main objective now is

removing the cast alloy side support that covers the cam belt

|

RETURN

TO PART 1 Jack

the engine up enough to take the weight off of the engine mounts.

|

|

|

Undo

the 15mm nut and bolt to the right side engine mount stabiliser bar.

|

|

|

Then

the x2 15mm bolts on top of the engine mount...

|

|

|

...and

x3 18mm nuts.

|

|

|

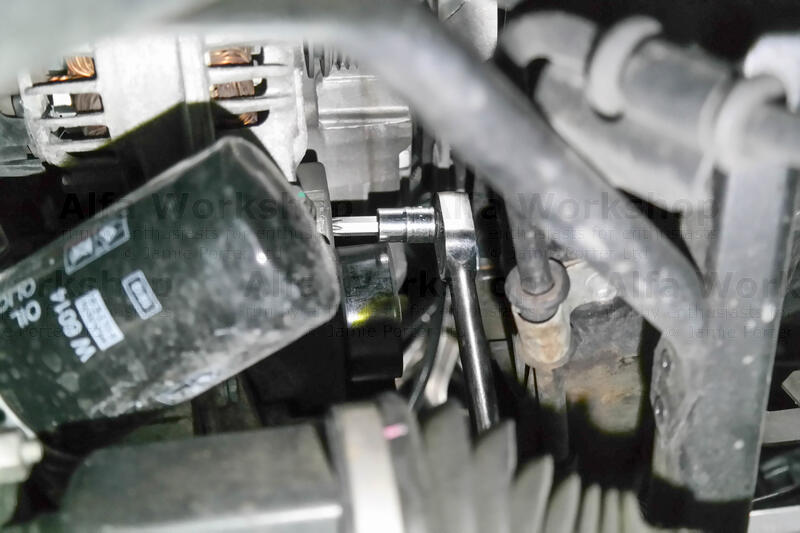

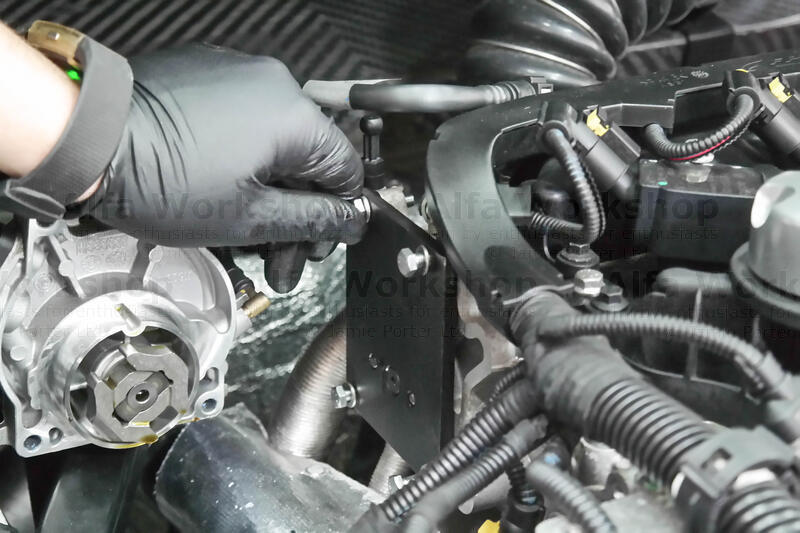

The

alternator has x2 10mm bolts to a plastic covering.

|

|

|

The

last alternator bolt is 13mm, once unbolted just lay the alternator down.

|

|

|

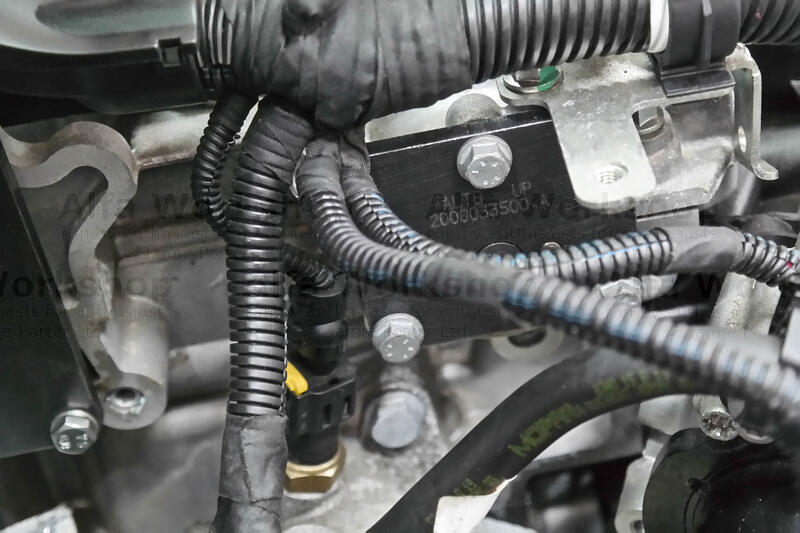

The

cam belt protective plastic covering has x5 5mm allen bolts. To the right of

the side cover unclip the pipe and electric trunking so that the cover can be

removed.

|

|

|

The

last bolts to the alloy side support are a 13mm...

|

|

|

....and

x3 15mm.

|

|

|

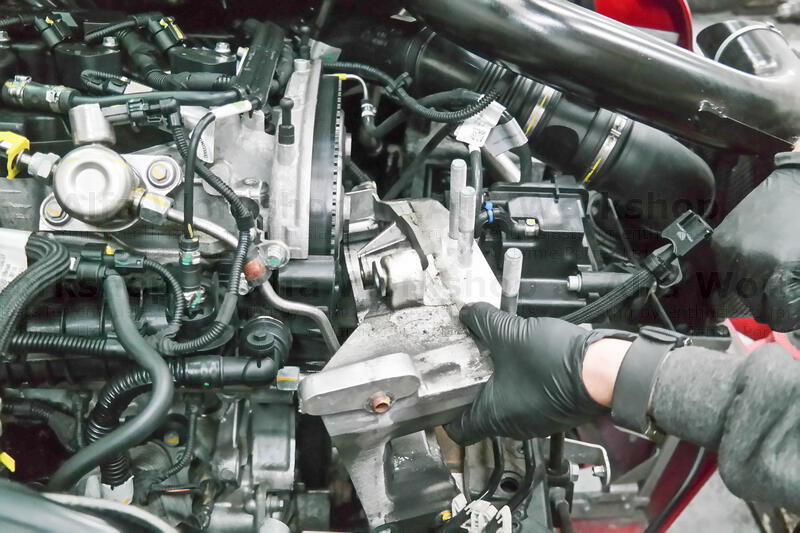

You

can now remove the alloy support.

|

|

|

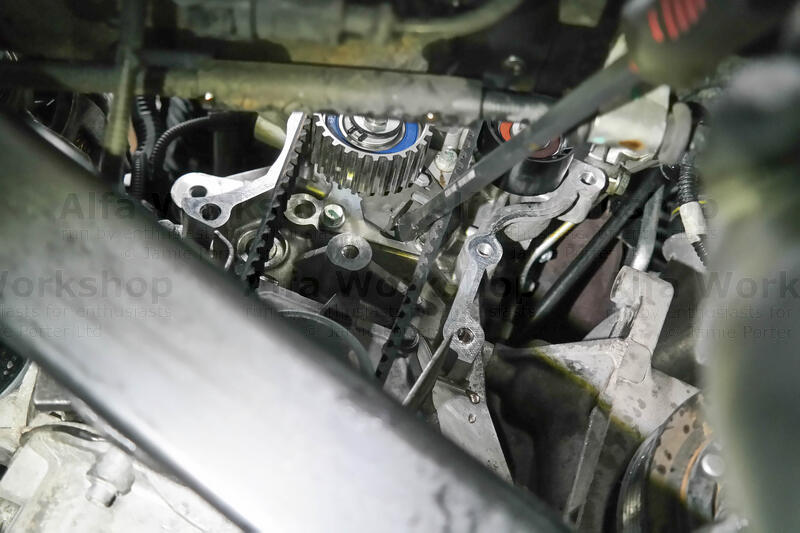

If

the exhaust camshaft doesn't align with the cam locking tool, release the

crank shaft locking tool and rotate the crank clockwise 180° then lock it

back up. You should now be able to lock up the exhaust camshaft.

|

|

|

Next

lock up the inlet camshaft.

|

|

|

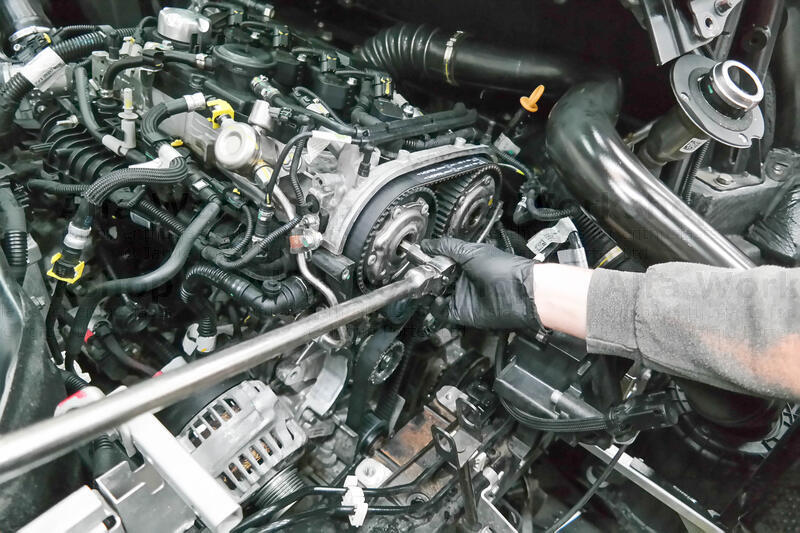

Undo

the 12mm bolt to the cam belt tensioner and remove. Take off the crank locking

tool so you can remove the cam

belt.

|

|

|

The cam belt idler has a 15mm bolt.

|

|

|

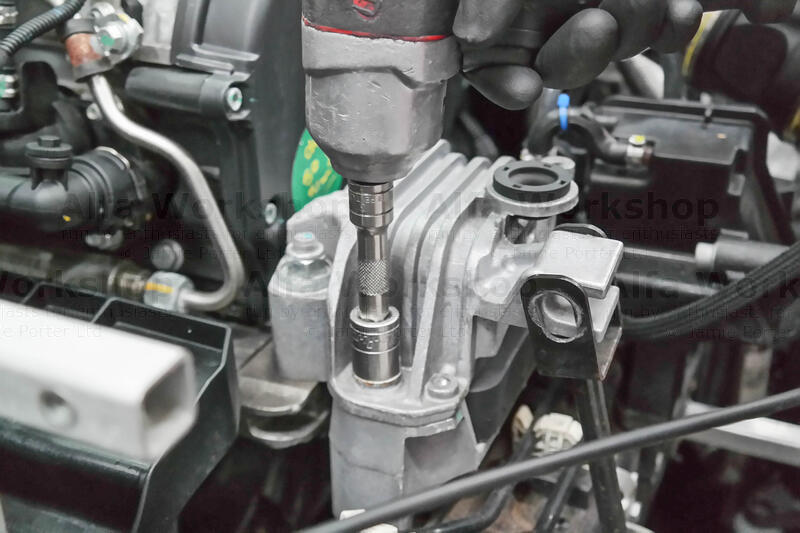

Undo

the 30mm caps on the camshaft pulleys.

|

|

|

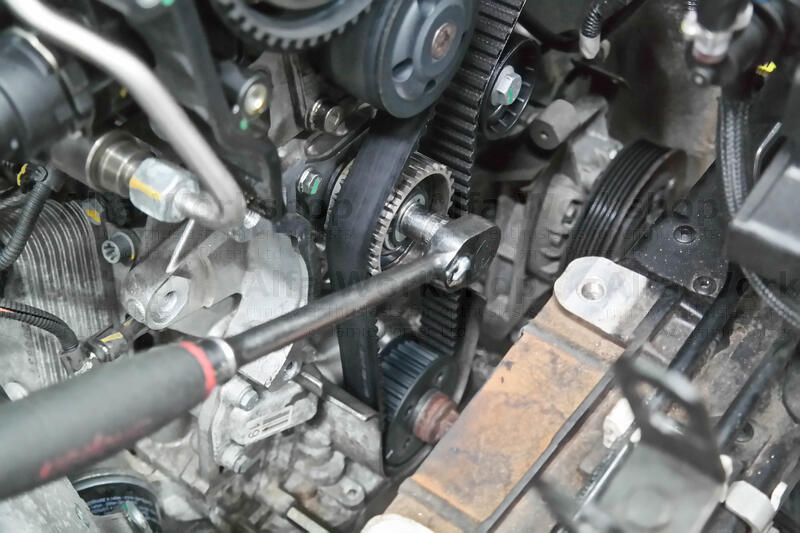

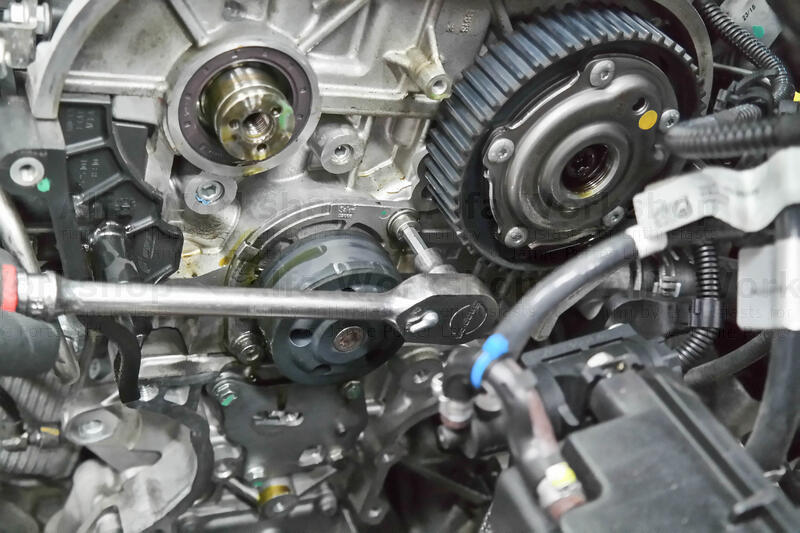

Loosen

the exhaust camshaft pulley so it can turn freely (T55

bolt) but take off the inlet pulley to gain access to the water pump.

|

|

|

The

water pump has x2 6mm allen bolts.

|

|

|

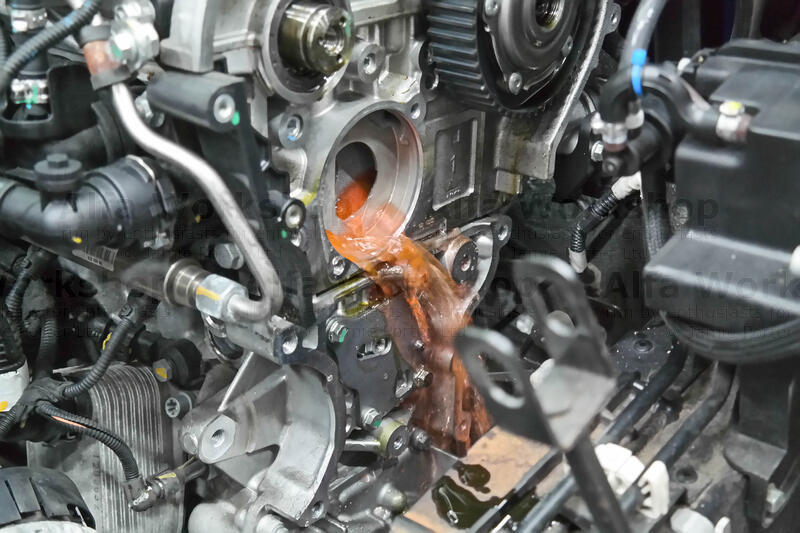

Put

a tray on the floor under the water pump to catch the coolant as you prise the pump off.

|

|

|

Clean

any residue and dry around the contact area where the pump has been lifted.

|

|

|

We

tend to apply a bead of gasket sealant around the 'O' ring of the new water

pump. Bolt on the new water pump.

|

|

|

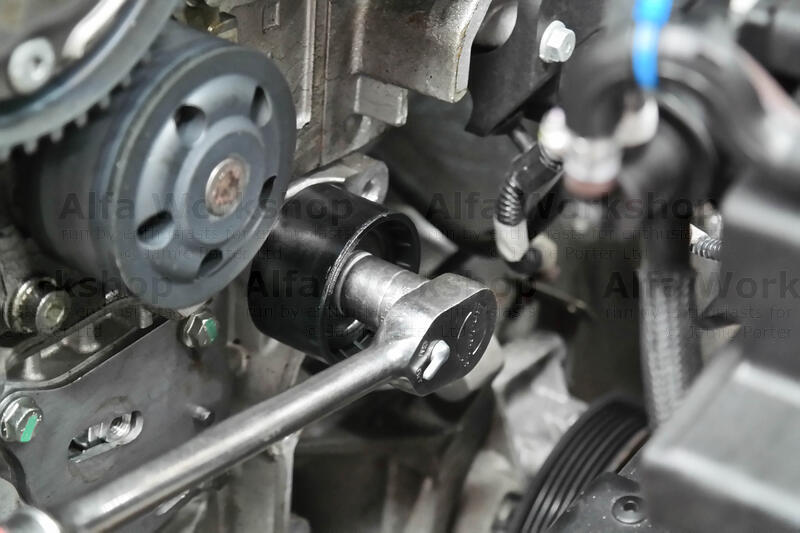

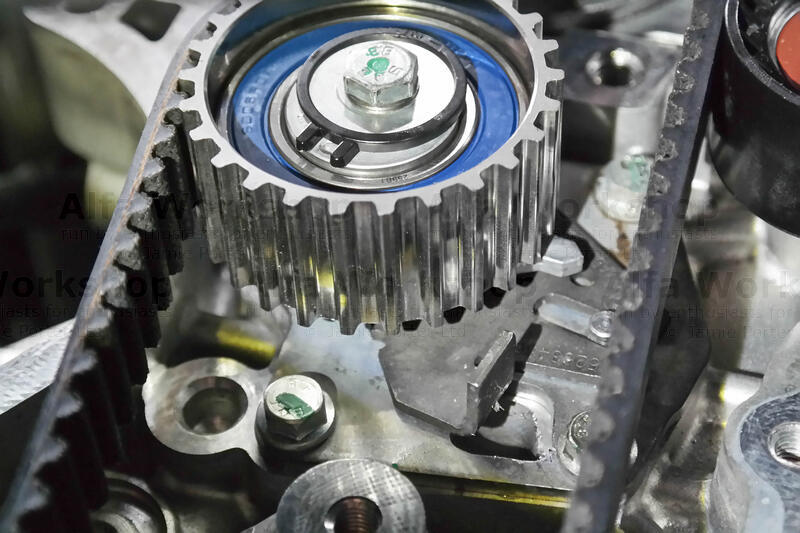

When

replacing the cam belt tensioner the lug on the support plate locates between

the fork on the tensioner, the fixing nut slides so just TACK the tensioner

on for now.

|

|

|

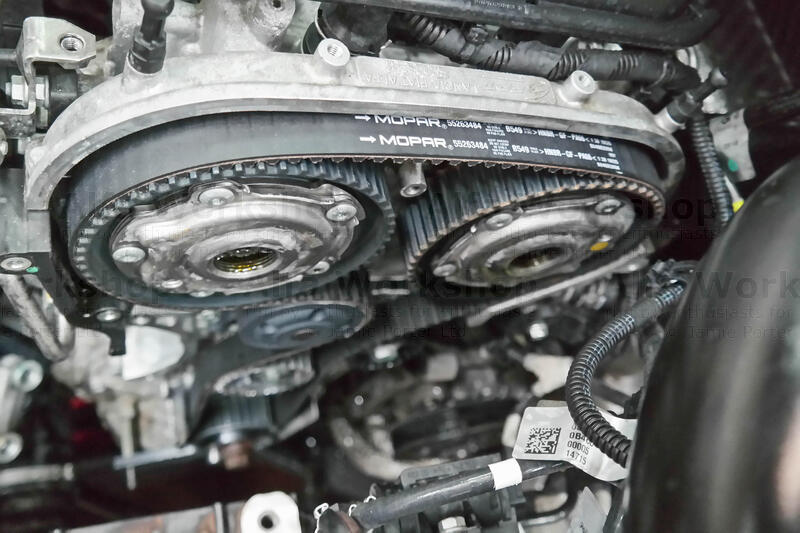

Loop

on the new cam belt noting the 'DIRECTIONAL' markings.

|

|

|

Using

a long handled FLAT head screwdriver rotate the base of the tensioner so that

the needle....

|

|

|

....points

to the hole on the tensioner fork, then tighten the mounting bolt.

|

|

|

Tighten

up both the cam shaft pulleys then take off all the locking tools.

|

|

|

Bolt

back on the blanking plate and vacuum pump using new gaskets.

|

|

|

Top

up the coolant tank to the MAXIMUM level.

|

|

|

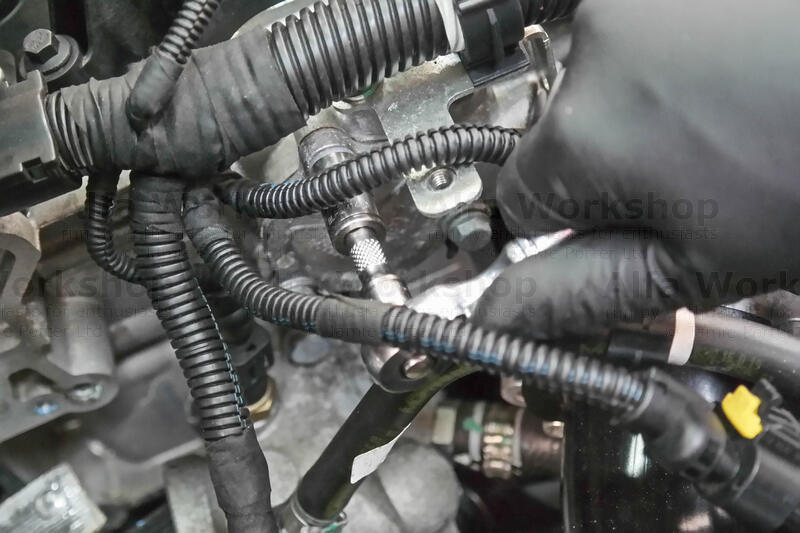

You

will need to bleed the system so undo the 8mm bleed screw...

|

|

|

...until

no air but just coolant escapes.

|

|

|

At

the Alfaworkshop we then pressure test the cooling system up to x1 BAR (14

psi) to check there's no leakage from the water pump.

|