TyrolSport UG Side Mount Intercooler - The new standard in upgraded Side Mount Intercoolers for 1.8T Golf/Jetta

(DYNO Testing) |

|

The aftermarket for the 1.8T has been booming, as people come to realize the potential of this stout motor in a relatively light chassis. Up until now, the upgrade path for the stock intercooler has been to replace the stock Sidemount intercooler(SMIC) with a larger unit, or to scrap it altogether and go with a Front Mount unit(FMIC). It has been held as common knowledge that SMICs are inferior to FMICs in all performance applications. Regardless of turbo, horsepower, vehicle use, FMICs have trumped SMICs in popularity. Part of this due to the fact that all the big horsepower cars run FMICs. The other part seems to be that it is inconceivable to many that an SMIC can indeed perform equal to an FMIC. The goal of the TyrolSport UG SMIC was to combine the performance of an FMIC with the cost and easy packaging and installation of an SMIC. We spent the better part of a day today testing three intercoolers. The stock sidemount, The TyrolSport UG side mount(Known as the UG SMIC in the charts below), and a front mount. The aftermarket FMIC will not be named for many reasons. The TyrolSport UG SMIC mounts in the stock location, uses stock hoses, and requires minor trimming to fit. The UG SMIC uses a bar and plate Bell intercooler core. The Front Mount is a popular unit, and resides on many 1.8Ts. We will not reveal the manufacturer of the FMIC, as the purpose of this test was data acquisition; not marketing, sales, or slander. Core volumes(LxWxH) for each respective unit were as follows: Stock 218 Cubic Inches UG SMIC 355.5 Cubic Inches FMIC 340.1 Cubic Inches Endtank volume was not measured, as the complex shape of some made it an exercise in futility. The FMIC appeared to have the largest endtank volume, and the stock IC appeared to have the least. The test car was a 2001 GTI equipped with an APR Stage 3, a Milltek catback, and an N75J valve. The car was equipped with a catalytic converter. We decided to use an APR stage 3 because the power level is in line with what most people shoot for. The car was mechanically sound, with no fault codes. The testing procedure was as follows. The already warm car was driven 20 minutes to the dyno, and strapped down. The engine and ECU were not touched before, during, or after the whole dyno process. Fuel trims were not reset, the battery was never disconnected, and no ice was placed on the intake manifold. The car was filled with Exxon 93 octane fuel from a local station prior to the dyno. In other words, no "tricks" were employed to skew the results(and believe me, we know many that can be used to spin dynos in a desired direction). Please note that all units were tested using SAE correction factor. All of the intercoolers were tested with a stock GTI bumper cover. When testing the sidemount units, we removed the right lower grill. When testing the FMIC, we removed the center lower grill. A fan was placed pointing towards the right lower grill for the SMICs, and then moved to the center for the FMIC. The stock unit was tested with the factory shroud in place. The UG SMIC did not use the shroud as it could not be fitted with the SMIC in place. The dyno order went as follows: UG SMIC, Stock SMIC, FMIC, UG SMIC. We did this in order not to give advantage to the UG SMIC as it was very cold outside on the way to the dyno. Each unit was run 5 times, approximately 2-3minutes apart. The timestamps are evident on the dyno sheets below. The car was idled between dyno runs, and was only shut off when swapping the intercoolers themselves. All runs began as close as possible to 2500rpm, and then went full throttle to 65-6700rpm.

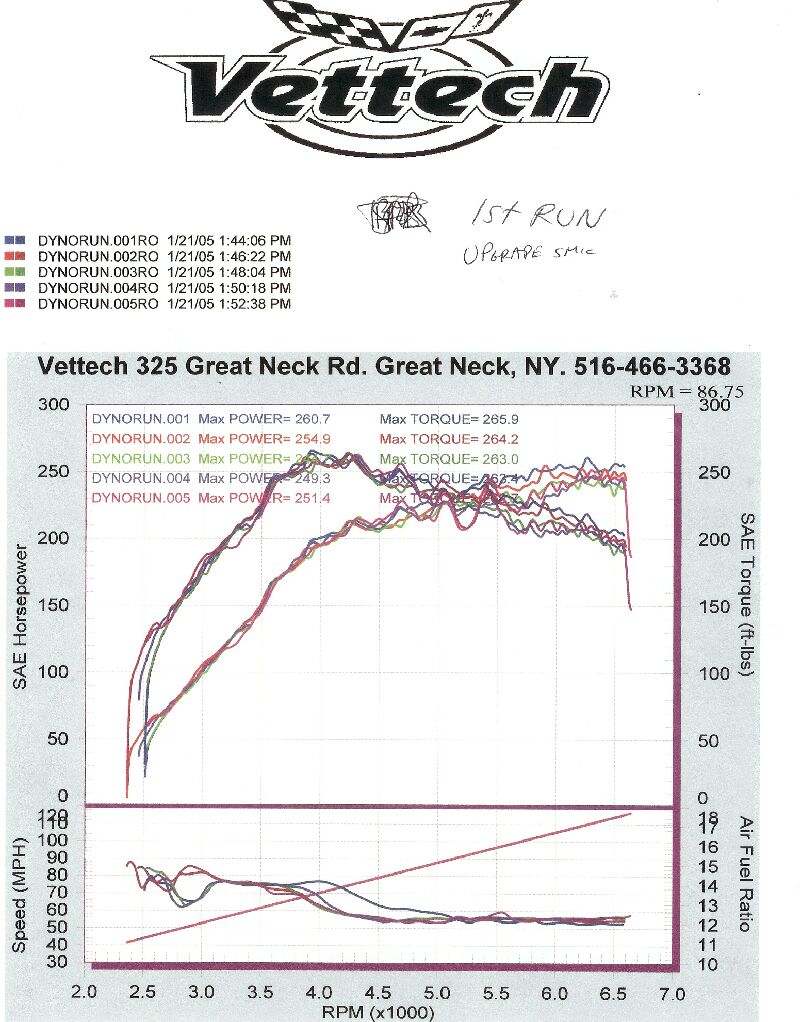

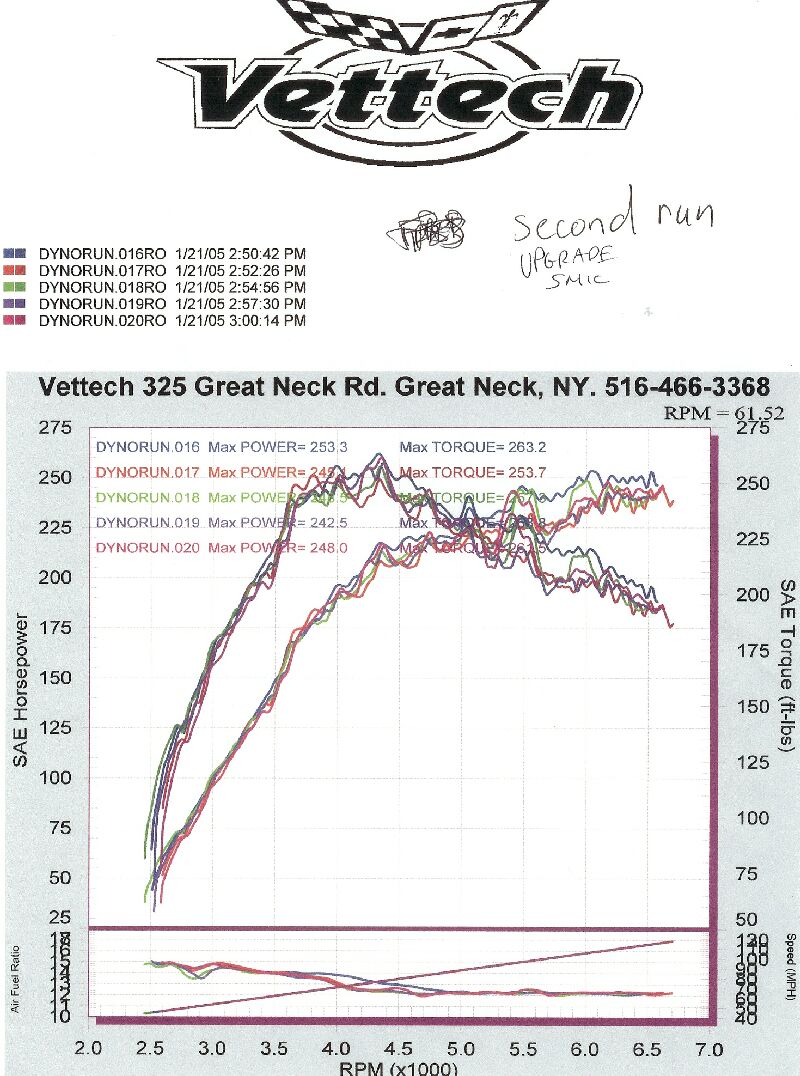

The bumper cover was affixed with two screws, and we practiced the intercooler swapping prior to the dyno. We were able to change them in approximately 10-15 minutes, with the car strapped to the dyno. Please be aware that we are not claiming that our FMIC results are indicative of all FMICs on the market, or that the unit we tested is the best unit available. We are also not claiming that our UG SMIC results are indicative of other SMICs on the market. The results presented are limited to the three particular units we tested today, and no others . These intercooler results also cannot be projected for higher horsepower vehicles, and we make no claims as to their accuracy when surpassing the whp levels presented in the test. The data will be shown in the order of the testing. The first 5 runs were on the UG SMIC, and are presented here:

This unit was very consistent in it's power delivery. Please do not look at the absolute numbers, but rather the changes between the five runs, as the power numbers are right in line with most "stock" APR stage 3s on pump gas. Since we are eliminating the first run, we will set the official max power of this unit at 254.9hp, and 264.2 torque. The next runs were with the factory sidemount:

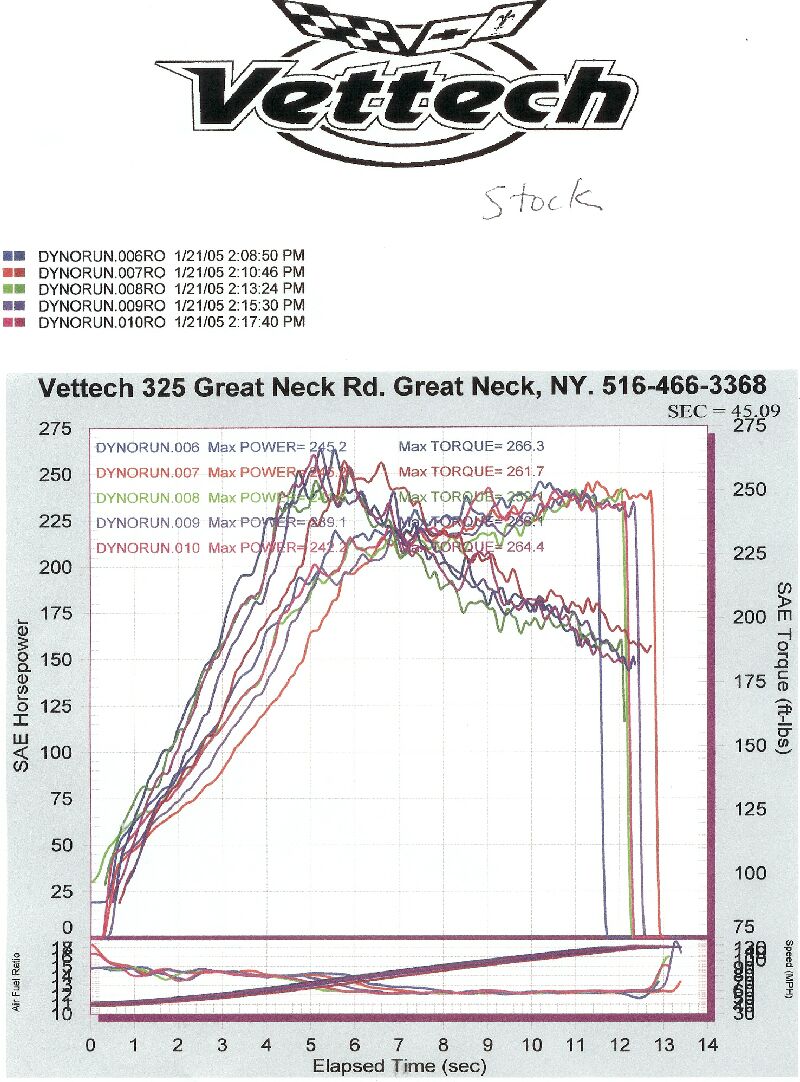

The first thing to notice is the huge inconsistency in the powerband with the stock SMIC. The other big news is the consistent power loss vs. the UG sidemount. Eliminating the first run, we get a max power rating of 245.2/261.7. One of the most interesting things we found is that ALL THREE units dipped to their lowest power after their respective third or fourth runs, and then began REGAINING power. Strange huh? Our hypothesis is that after the third run, the ECU began adapting to each respective IC to maximize it's power potential. This is purely conjecture, but is very interesting to note. Again, the ECU was not cleared at any time during this test. After the Stock SMIC, we installed the FMIC and began testing:

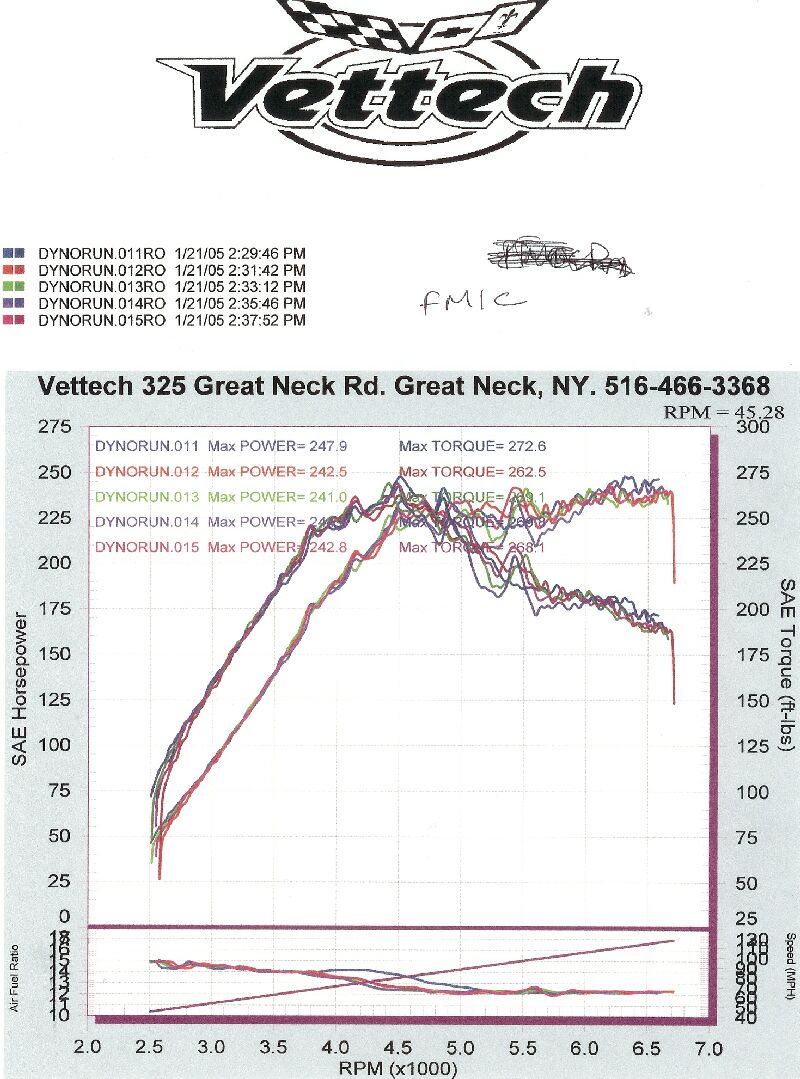

To our surprise, it showed some improvement in midrange torque, but overall horsepower was very similar to the stock SMIC! Eliminating the first run, the max power came on the fourth run, with 244.6 horsepower, and 269.8 torque. To verify that our first few runs on the UG SMIC were not flukes on a "cold" motor or IC, we reinstalled it after the FMIC. To our surprise, it actually performed better than the first time around. Here is the second set of runs of the upgrade SMIC:

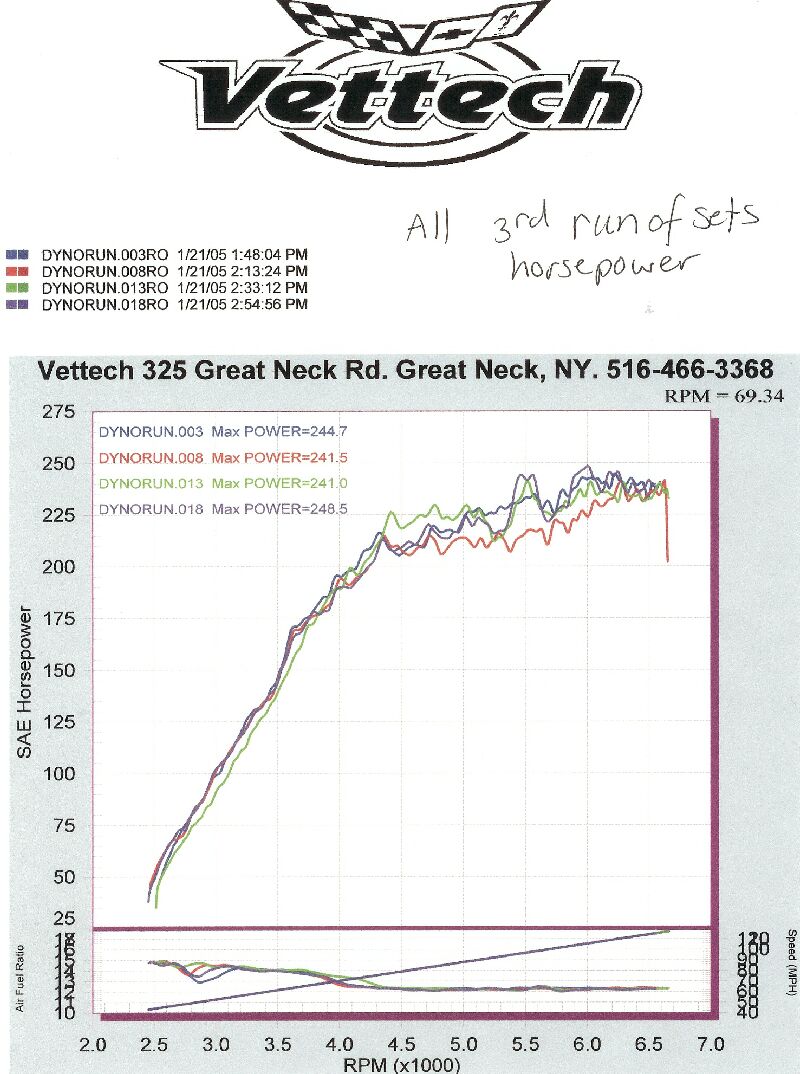

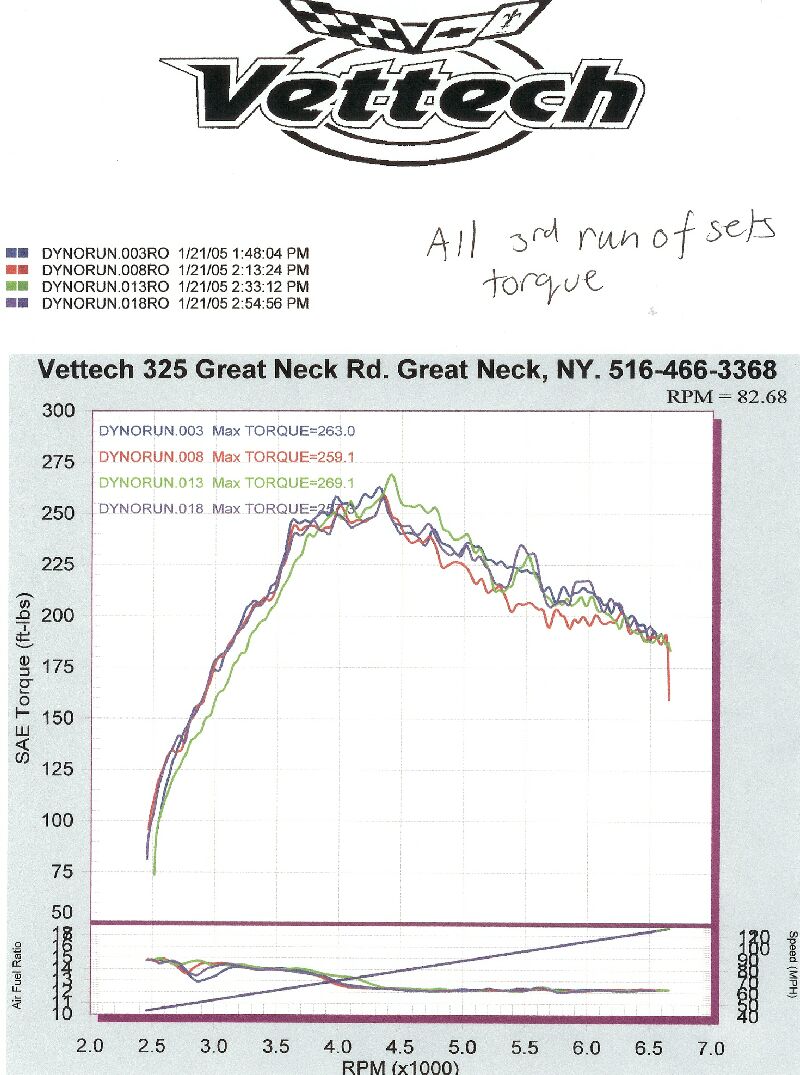

To make this analysis easier, here is the third of five runs for all the intercoolers, from the horsepower perspective, followed by the torque perspective. Stock SMIC is RED, FMIC is GREEN, UG Sidemount is BLUE and PURPLE:

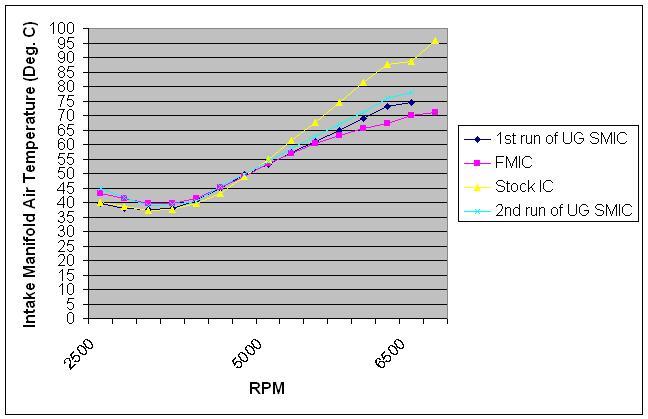

The FMIC has a bump in midrange HP and Torque, but is equaled or eclipsed by the SMIC at higher revs. The stock SMIC trails significantly. We were not going to let these intercoolers off so lightly. Why was the FMIC not producing the power it should be? What are boost and power levels? For that, we turn to the VAGCOM datalogging. We first looked at Intake Air Temperature. The following chart is an average of the last four runs(first run eliminated):

Next we analyzed boost levels:

Still no answer on why the FMIC did not produce the results it should have. Here is a chart on ignition timing for all the units: The Upgrade sidemount shows the least amount of timing advance during spool, yet makes more power during that timeframe. (Whether a function of the increased boost level shown above, or perhaps less restriction). Up top, We see part of the reason why the FMIC is down on power; it shows the least timing advance in the 5500-6000 rpm range, which should be where the peak power is produced. Now why on earth would this happen? Here

is an analysis on knock voltages on Cyl1(first chart) and Cyl2:

The fact that both stock and FMIC are showing much higher knock correction in the upper RPM range explain the poor power results. This is not going to be the last test of these three units. As soon as the snow clears here in NYC, we will be testing all three units again, but this time on a closed course. We will be running the units from 60-120mph, in two directions, on the same day, using VAGCOM datalogging. This will separate the men from the boys. As for now: Myth: SMICs are always inferior to FMICs. BUSTED. UPDATE! Highway testing now completed. Here's the Highway testing data. More detailed pictures here. |

TyrolSport

(917) 626-3368

info@TyrolSport.com

© 2005 TyrolSport

Site Design by GRC Designs, LLC

![]()