2018

Grand Cherokee (WK2) Mopar Rock Rail Installation (P/N 82213525AD)

So,

after multiple dealerships told me that this part would not work for our new

2018 Trailhawk I ordered a set. Sources on the forums

said they would fit and since they come as a factory installed part why

wouldn’t they? Lots of good write ups and videos, but the AD revision was a

little different- they no longer provide a tool for the door sill bolt

installation, the door sill bolts are flange head without washers (factory

instructions not yet updated), the flag bolts have been standardized, no pinch

weld stiffener bar, and I’m sure other things I have not noticed.

My

pics and comments below are meant to supplement (NOT replace) the Mopar

provided instructions:

Latest 82213525AD Mopar Rock Rails

Installation WK2

Additional

links to forum info and video can be found here: http://www.billswebspace.com/GCTH.html#JeepWK2RockRails

NOTE: The

following

is provided for

information only and any use of this information by you is at your own risk.

To

start, I put our Jeep in Offroad 2 and Jack modes,

plenty of room to work:

I

then removed ALL plastic rivets from the plastic sills we would be replacing as

well as the single bolt out back (10mm socket)- a trim tool makes quick work of

the plastic rivets and all came out easily except for a few, wire cutters to

the rescue:

With

doors open, the next step was to unclip the OE plastic skirts. I started using

a plastic trim tool and then just pulled them off carefully. No worries about

breaking anything, these are throwaway parts that you can elect to cut up for a

more finished looking installation……I did not.

Pulling

the plastic sills off can pull the sheet metal out around the door sill

mounting holes, I used a plastic mallet (rubber would work too) to lightly tap

them flat again…. logic being it would make it easier to start the nuts on the

bolts installed here later with a flat surface when the rock rails are put into

place.

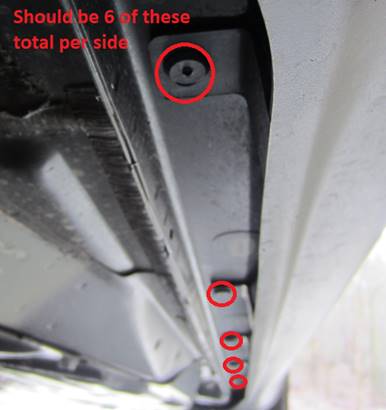

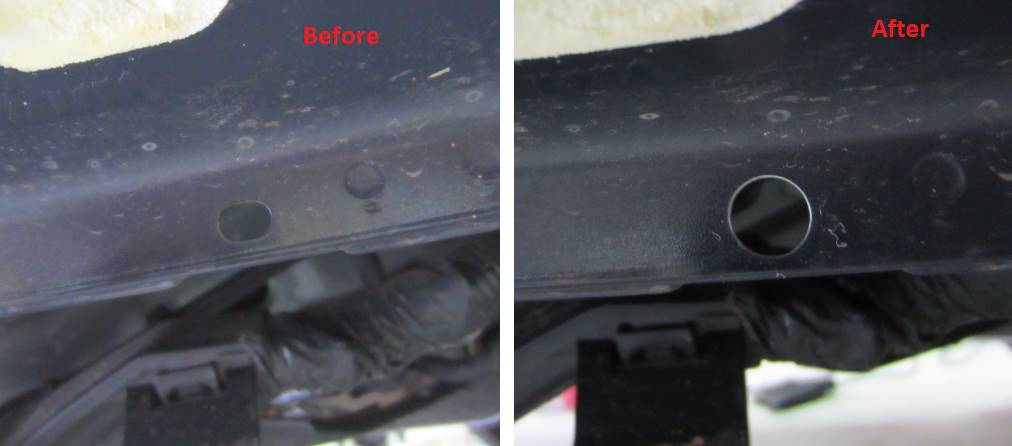

I

did not have grommets to remove under the sill/beside the pinch rail, Jeep

decided to ditch those and now uses plastic stickers to cover the holes. These

were removed by carefully inserting a razor blade and then using pliers to pull

off, all removed on both sides- (6) per side.

Remove

(4) bolts with 10mm socket for wiring harness on passenger side, let it hang.

My

wife helped out with prep by making sure ALL the nuts and bolts worked as

desired. Welding slag and powder/coat/paint have a way of gumming up what

should be a super smooth engagement. I fortunately have a thread restoration

kit which works better than a die/tap since it should not remove any additional

metal, just the paint/powdercoat/slag. This was used

on ALL problem bolts/nuts to achieve the goal of being able to hand start and

tighten ALL, flag bolts and nuts the most critical.

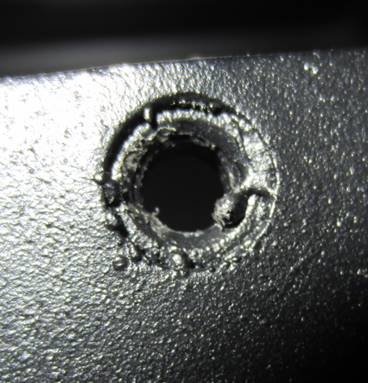

While

my wife worked on the above prep, I drilled out holes as provided in the

factory instructions. The front and rear rivet holes were drilled out using an

11/32 drill bit. The pinch rail holes were drilled out with a step bit to 10mm,

be careful on the passenger side to avoid the wiring harness.

The tab at

the rear has to be bent up, this was a two-step process. I didn’t have a bottle

jack like some others have used but I did have a regular jack and jack stand. I

removed the upper jack stand support from the base and turned it upside down on

a floor jack, it fit perfectly into the tab to jack up and bend it. At that

point the tab still has to be bent as flat as you can get it, I used pliers to

bend the remaining part down and then finished with a crowbar and a rubber

mallet as a fulcrum point on the tire- that eliminated the need to remove the

tire and use a hammer.

Now the real

fun begins…. cleaning the foam out of the sill cavity. Different ways to do

this, I used a flat head screwdriver in top and bottom holes to loosen and

break apart foam and a shop vac to remove. I didn’t try and remove all foam,

just what I thought might get in the way of fishing bolts through the bottom

holes to the door sill holes.

There were

two holes per side that would not be used, I covered them with exterior vinyl-

cannot be seen once rock rails are on.

These were my tools for

installing the door sill bolts/retainers: ¼ extension, ¼ flex joint, mid length

13mm socket and a small piece of Butyl Seal Tape. The seal tape is sticky so I used a small

piece (a little smaller than the piece pictured below, adjust size to desired

level of sticky) over the face of the socket to adhere to the bolt so none

would fall out- worked perfect, no dropped bolts and only sticky enough to hold

the bolt until I needed to retrieve the socket assembly, easily removed.

A 13mm deep socket was used to press the

retainer over the installed bolt after a screwdriver was put in place to hold

bolt. The entire process went a lot faster than expected.

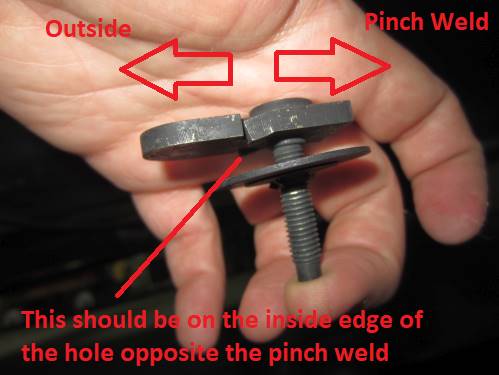

Flag bolts installed next, the washer and

retainer can be pre-assembled, halfway on the flag bolt is a good starting

point for the retainer until you see what you are working with to get it in the

hole. I like to lightly thread the nut on one more time to make sure it takes

very little effort and will not cause the flag bolt to turn before biting

(shouldn’t happen with new style flag bolts)- remove nut before proceeding.

Tuck the

breather hose back in on the driver side…….

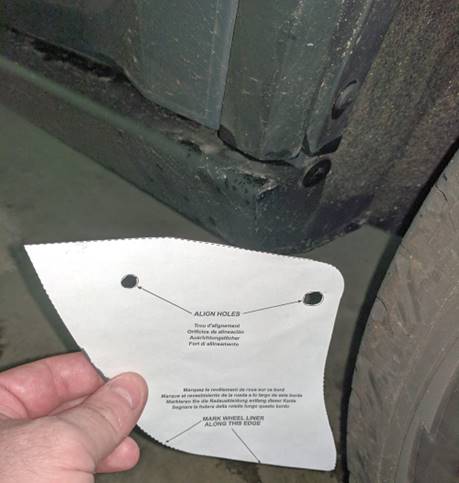

You will need

to use the provided template to trim the rear wheel well liners, but it does

not line up exactly- I had to make further adjustments after the rock rails

were installed.

**DON'T

FORGET BLUE (MEDIUM) THREADLOCK** (I added some to the door sill bolts and

pinch rail screws, as well as the flag bolt nuts before installing the rock

rails)

Fortunately, I had three people for the next step…. could be done alone but

much easier with more 😊 I lifted the rock

rail into place and lined up the three flag bolts and loosely started the nuts.

Up top and on either end my wife and son made sure the rear wheel liner was on

the inside of the rock rail, then lined up the door sill bolts and loosely started

all of those nuts- no issues so far, prep is everything. Next a jack was placed

under the rock rail and lifted until the pinch rail screws could all be

installed loosely but almost hand tight……then the flag bolts were tightened,

the pinch rail screws were tightened, and the door sill bolts were tightened.

Nuts and screws in below pictures were NOT tightened so don’t get thrown off by

the pictures.

Last but not

least, line up the felt wheel liners and chassis/rock rail holes and insert

plastic rivets with push pins provided, (2) in front and (1) in back. I used a

short Phillips screwdriver to line everything up before inserting the plastic

rivets.

All DONE 😊